- #CREATE YOUR OWN TOOL PATH IN CAMBAM PDF#

- #CREATE YOUR OWN TOOL PATH IN CAMBAM 64 BIT#

- #CREATE YOUR OWN TOOL PATH IN CAMBAM 32 BIT#

- #CREATE YOUR OWN TOOL PATH IN CAMBAM SOFTWARE#

#CREATE YOUR OWN TOOL PATH IN CAMBAM 32 BIT#

It should work in any 32 bit windows operating system.

#CREATE YOUR OWN TOOL PATH IN CAMBAM 64 BIT#

The program is a Windows program, and is known to run on Windows XP and Windows 7 (32 & 64 bit versions).

#CREATE YOUR OWN TOOL PATH IN CAMBAM PDF#

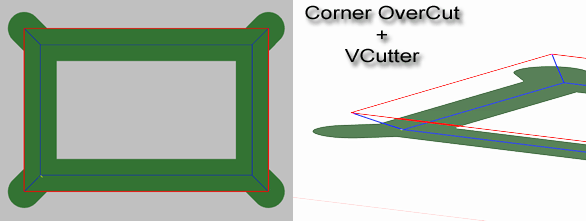

The program, pdf help file, a readme file and source code are included in the zip file.ĭownload the G Code Wrapper Program. It is highly unlikely that sizes of less than 0.1mm/1 degree would ever be noticeable on the work and such precision wouldn't add greatly to the machining time. For large arcs it is specified by segment length, and for tiny arcs it's possible to specify the maximum angle the segment subtends around the centre of the arc. The user has control over the straight line segment size. All arcs are converted within the program to straight line segments before being treated in the same way as normal straight lines. All straight lines with a component in the wrapped axis are converted into rotations and a movement in a the machine's X axis only. The program works by reading and understanding the toolpath. Letter height is 1.5mm, depth of engraving 0.15mm. There is even room in the shape to make a feature of the hallmarks too. Here's the engraving wrapped from the 2D drawing, path created in CAMBam and then wrapped onto the ring. The engraving on the cap ring of my prototype CNC machined pen.

When the Y axis was wrapped onto the A Axis, with a 15mm work diameter, the Mach 3 toolpath is as below: When the X Axis was wrapped onto the A Axis, with a 75mm work diameter, the Mach 3 toolpath is as below: To give an example using a toolpath that engraves 'Hello' (red dotted line = rapid feed, blue line = machine feed & magenta arc = arc - notice how the wrapped versions of the letter 'O' are no longer arcs): Either the X or Y axes can be wrapped and three settings can be tweaked to change the radius & machining plane.

The program wraps an XY plane toolpath around the A Axis. So, I decided to write my own wrapper program. There are a lot of functions in CNCWrapper I do not understand or don't need that I feel I'd be required to pay for.

#CREATE YOUR OWN TOOL PATH IN CAMBAM SOFTWARE#

Now, I am constitutionally unhappy about paying for software if I don't need to, and I am even less happy to pay for stuff I'll only rarely use. CAMBam can create a toolpath for a 2D toolpath type arrangement, and 'CNCWrapper' does the wrapping. In order to be able to engrave the surface of a pen, you either have to create engraving programs using the X & A axes by hand (because almost no programs exist that allow this sort of idea) or you create the toolpath as a flat shape, then wrap it around the surface. I have only recently started using a CNC machine and want to use it for making pens.

CNC G Code Wrapping CNC G Code Wrapper Program Download

0 kommentar(er)

0 kommentar(er)